Previous ASME Award Winner

Recent Departmental Runner Up Awards

Capstone Design Projects

Animal Care Processing Project (ACCP)

2024-2025 - Spring

Team: 42

GA - Foam Shell Culling Station

2024-2025 - Winter

Team: 1

Team Members

Tobin Boshaw

Matthew Pope

Collin Huang

Samuel Hasegawa

Kenny Ochoa

Brandon Lopez

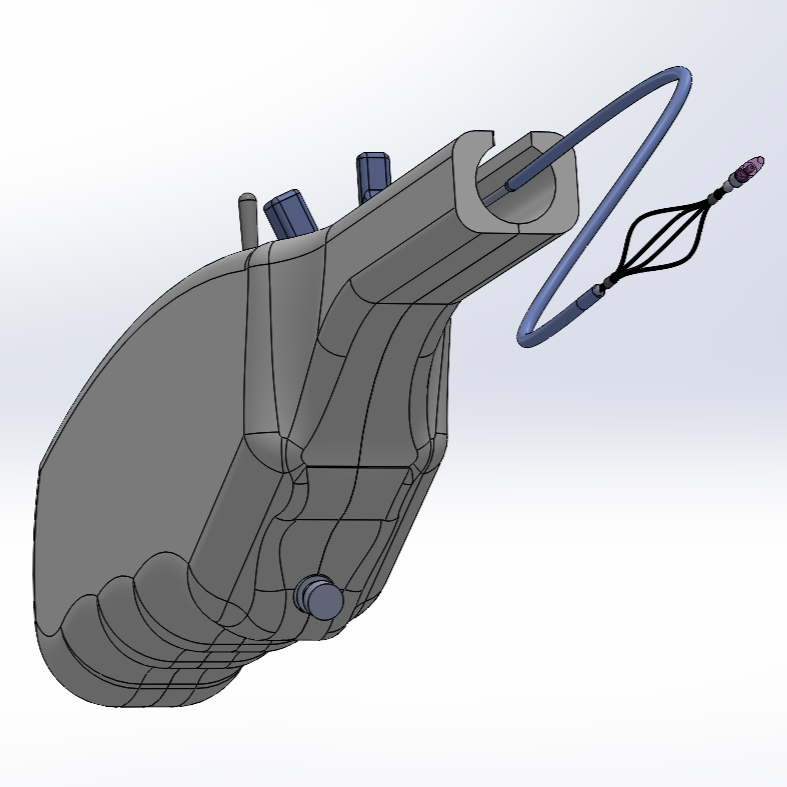

Bidirectional Guide for Treatment of Peripheral Artery Disease

2024-2025 - Spring

Team: 21

Kinetic Craft Center Sign

2024-2025 - Spring

Team: 6

Automated Cognitive Touchscreen Training System for Mice

2024-2025 - Winter

Team: 8

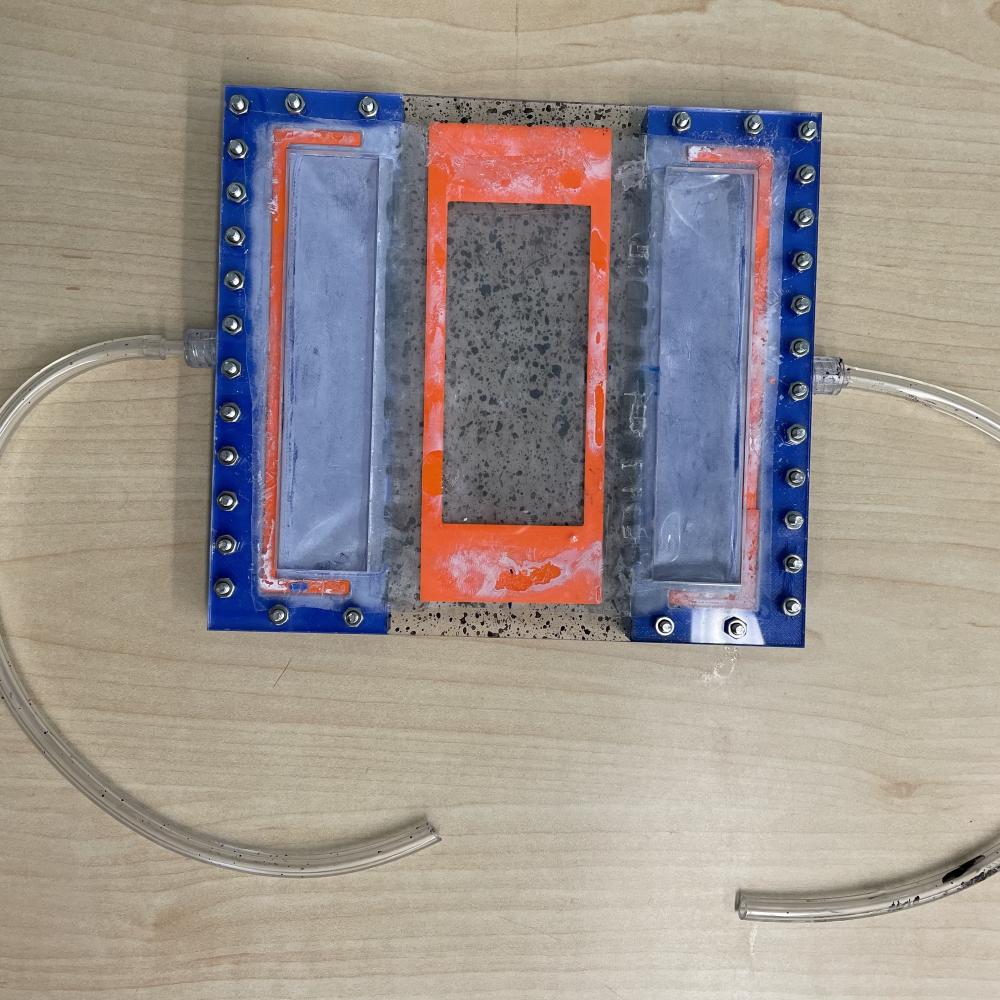

Cell Stretcher 2.0

2024-2025 - Spring

Team: 29

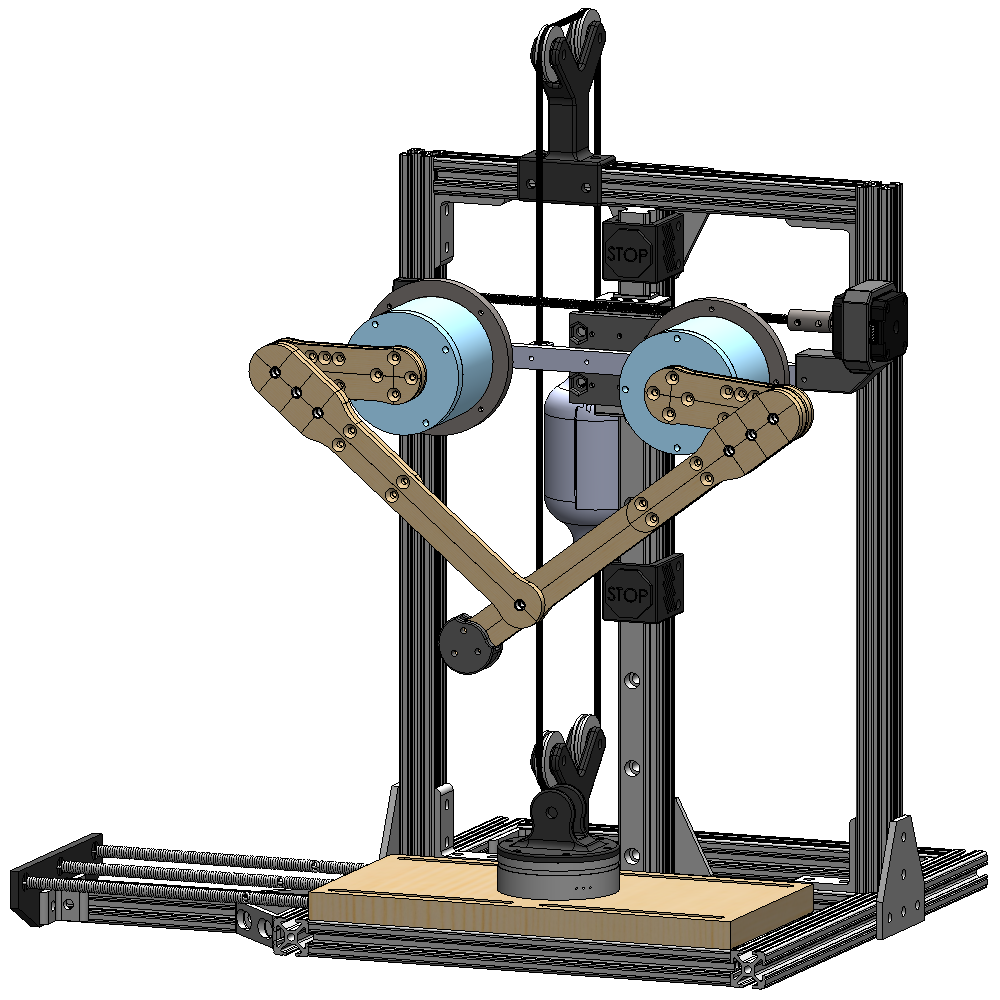

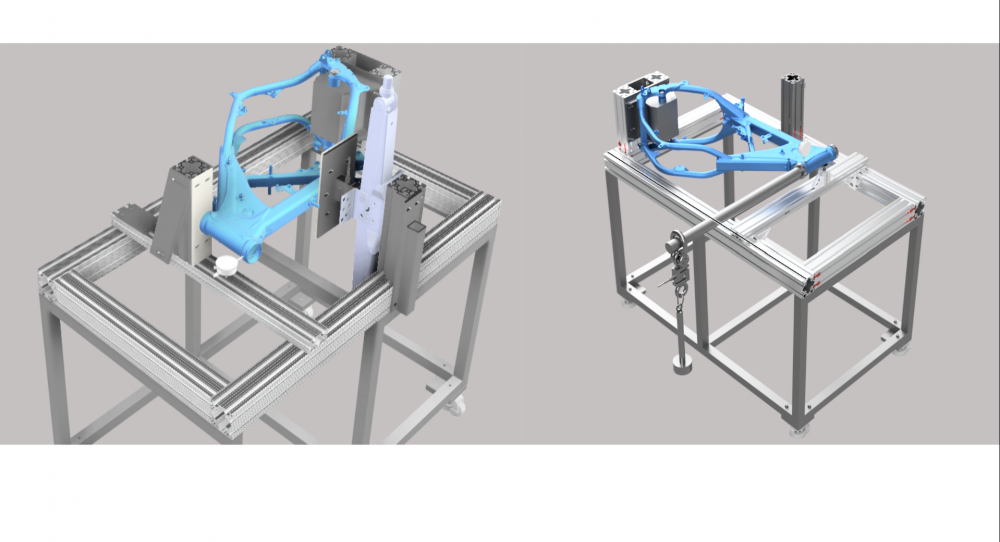

Design and Analysis of a Mode-Transitioning Robotic Leg and Test Bed for a Hexapod Rescue Robot

2024-2025 - Spring

Team: 37

Team Members

William Harris

Lucas Yager

Giovanni Bernal Ramirez

Hwuiyun Park

Elias Smith

Endovascular Device for Rapid Blood Clot Removal

2024-2025 - Winter

Team: 12

Carbon Blade Carbon Capture

2024-2025 - Spring

Team: 15

Team Members

Ian Cosgrove

Charlie Frank

Juncheng Li

Alexandra Rodriguez

Konrad Stromayer

Materials Break Up

2024-2025 - Spring

Team: 16

Cellxercise Machine

2024-2025 - Spring

Team: 2

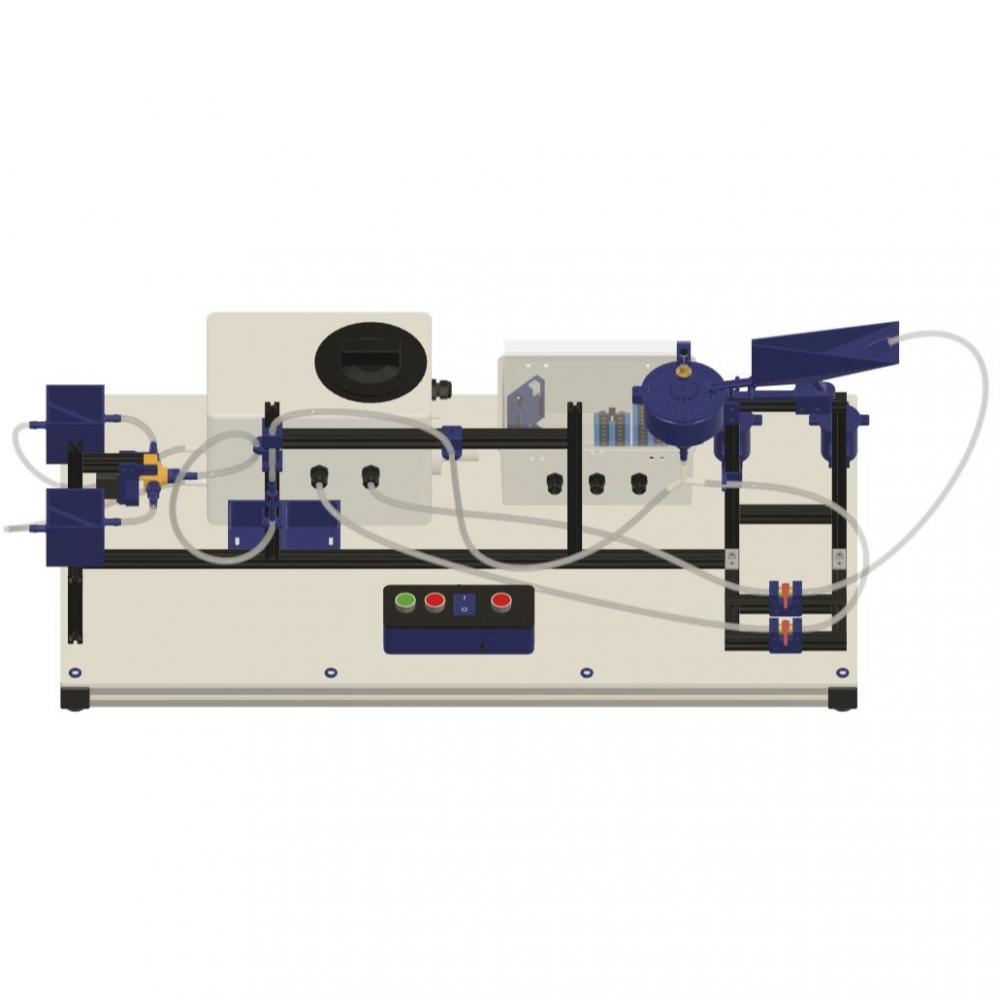

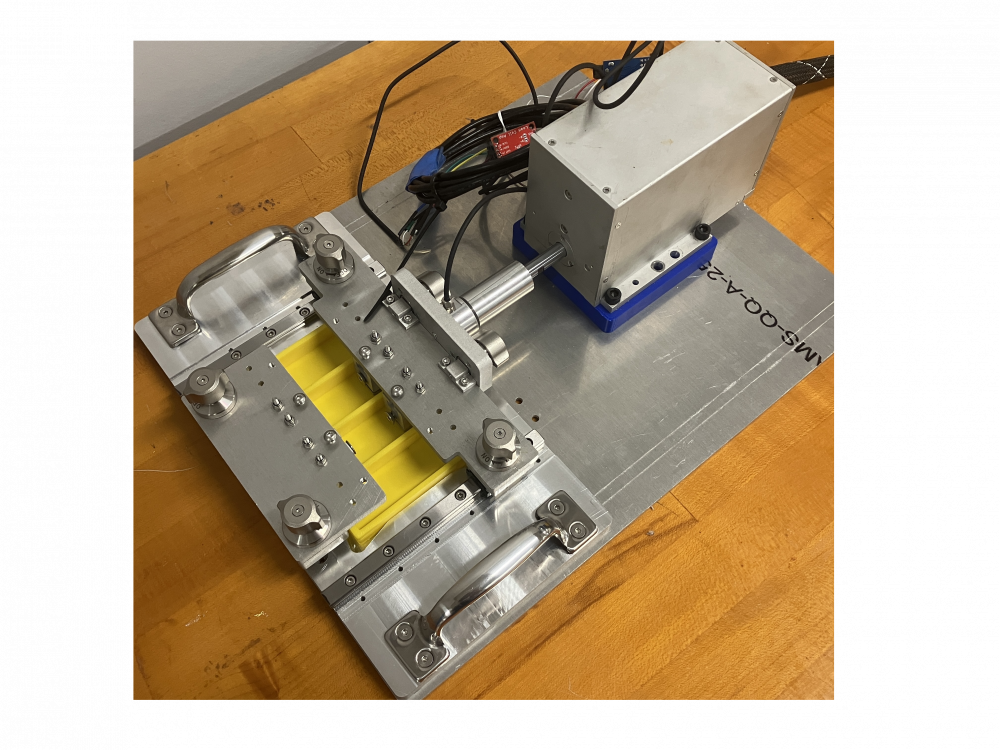

Sample Throughput Optimization for Thermal Desorption Spectroscopy

2024-2025 - Winter

Team: 15

Team Members

Ethan Greene

Jamie Lee

Saul Rios

Leo Serbinov

Vedanth Talla

Brayden Wong

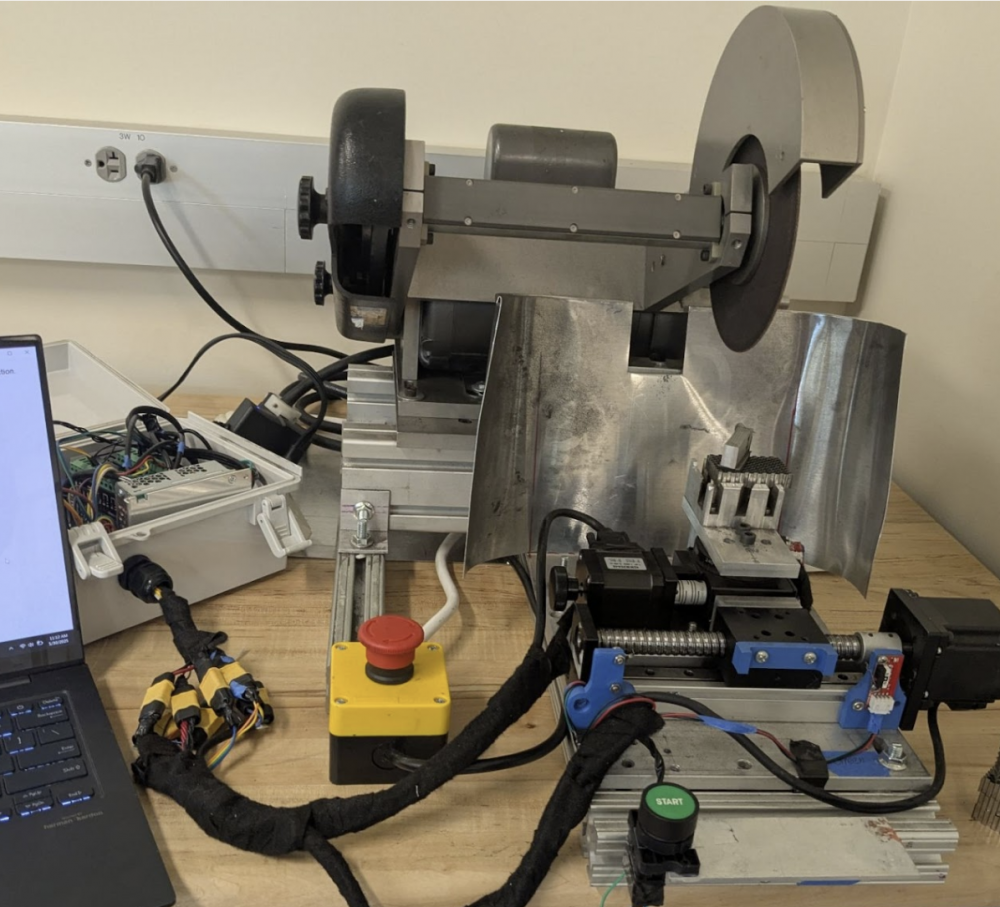

ShockE Frame Stiffness Test Fixture

2024-2025 - Spring

Team: 19

Resistive Torque Measurement Apparatus

2024-2025 - Spring

Team: 24

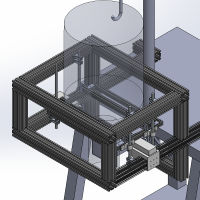

Automating the Cutting Process Hi-Tech Honeycomb

2024-2025 - Spring

Team: 38

Team Members

Rowan Barg

Micah Borg

Elijah Matthews

Daniel Sun

Acoustic Modem Integration onto Wave Glider USV

2024-2025 - Winter

Team: 16

SomnoStay - A Novel Oral Appliance for Obstructive Sleep Apnea

2024-2025 - Spring

Team: 7

NIWC PAC UAS Launch and Recovery

2024-2025 - Spring

Team: 26

Team Members

Parker Amano

Gregory Garner

Gabriel Lepage

Bhodivista Yohn

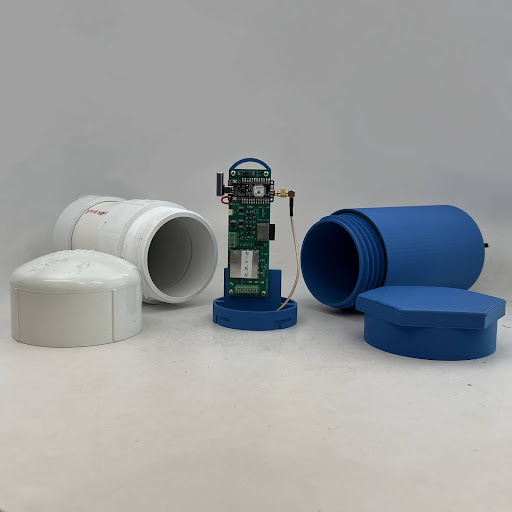

Outdoor Low Power Measurement Equipment Enclosure (ENTS Enclosure)

2024-2025 - Winter

Team: 11

Team Members

Fayza Elshafie

David Fisher

Michael Gonzalez

Benny La

Elliot Snyder

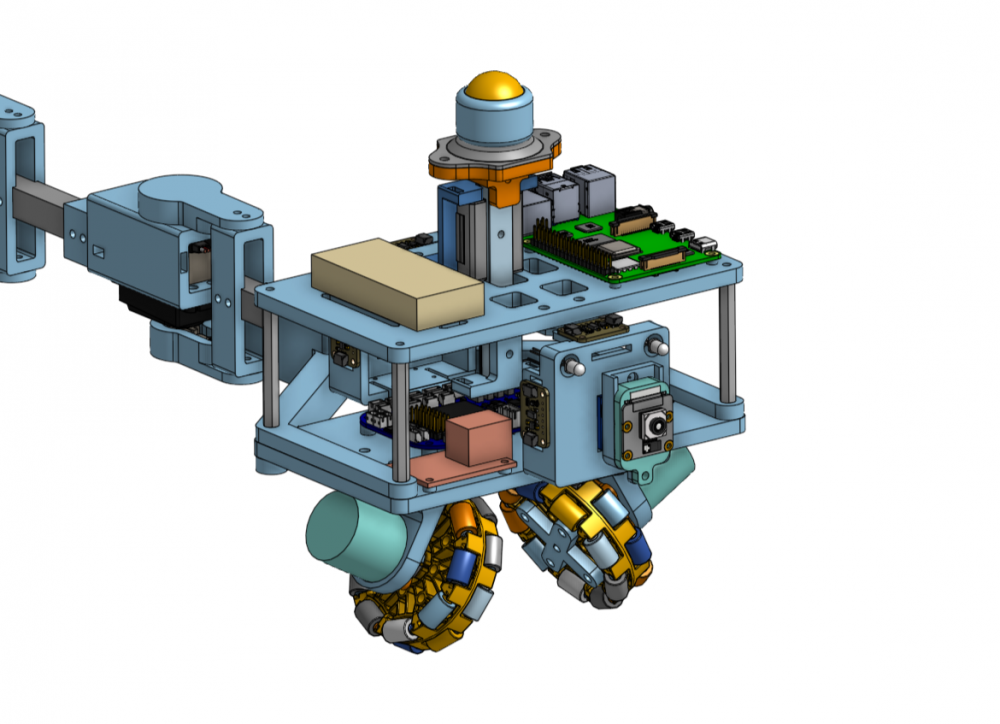

Manual In-Pipe Robot Surrogate for Autonomy Development

2024-2025 - Spring

Team: 18

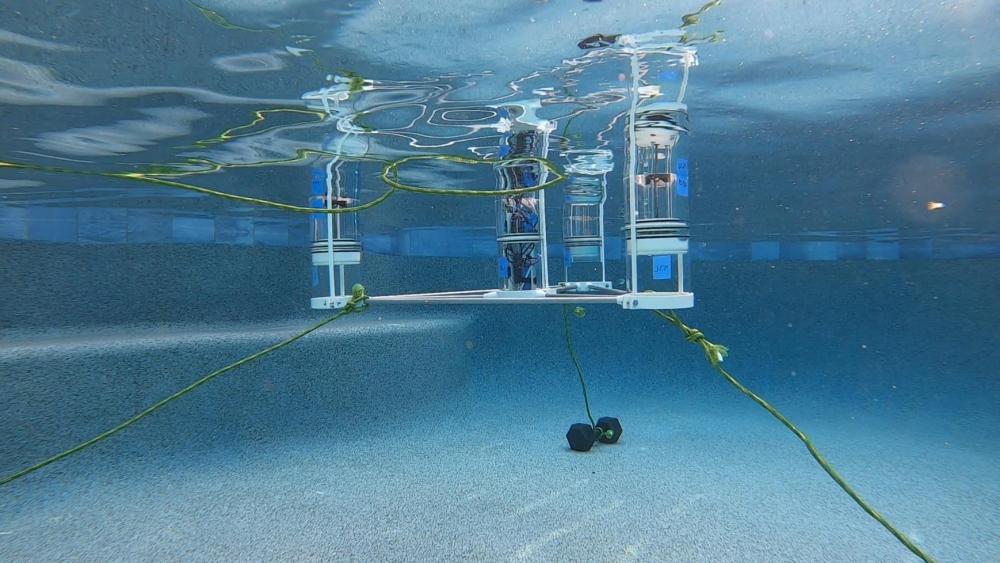

Wave Energy Converter

2024-2025 - Spring

Team: 25

DM Consulting - Dry Dock Block

2024-2025 - Spring

Team: 8

LightLok - Burn Prevention

2024-2025 - Winter

Team: 13

Solar Wind Tunnel

2024-2025 - Spring

Team: 32

Team Members

Benjamin Marsden

David Bori

Max Gonsalves

Rachel Gillespie

StableWind Technologies

2024-2025 - Spring

Team: 17

Team Members

Wills Moore

Christopher Mansfield-Reid

Trevor Marshall

Christopher Cordano

Jintong Han

GA Autoloader Recovery Fusion

2024-2025 - Spring

Team: 9

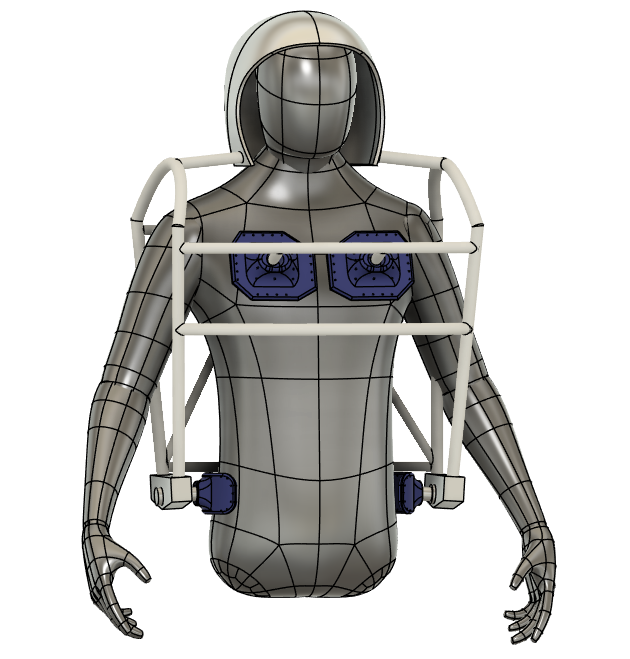

Halo Helmet Platform

2024-2025 - Winter

Team: 9

This project introduces a helmet-integrated roll cage that redistributes impact forces away from the head and neck. Anchored to the upper body via a harness, the system disperses forces more effectively, reducing the risk of traumatic brain and spinal injuries.

Regenerative Trailer Braking System

2024-2025 - Spring

Team: 3

Device to Assess Nitric Oxide at PoC

2024-2025 - Spring

Team: 20

Team Members

Fernando Rico

Li-Pin Chang

Armaan Goklani

Hi Tech Honeycomb Automation

2024-2025 - Spring

Team: 10