Previous ASME Award Winner

Recent Departmental Runner Up Awards

Capstone Design Projects

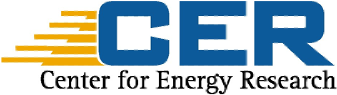

Solar Turbines Alignment Mechanism

2020-2021 - Spring

Team: 5

Team Members

Nigel Coseip

Alberto Guardado

Vicente Lopez-Espinosa

Daniel Lopez Villa

Nicholas Pereyda

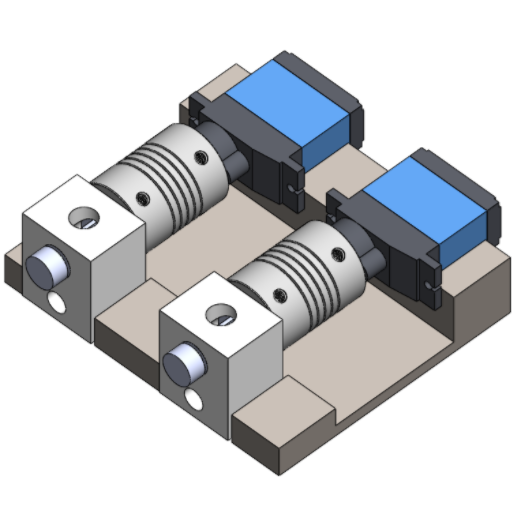

Precision Hydrogel Injector

2020-2021 - Spring

Team: 10

Trifinger Robot

2020-2021 - Winter

Team: 3

Team Members

Jan Dustin Tengdyantono

Jonathan Goenadibrata

Joseph Murad

Sebastian Podiono

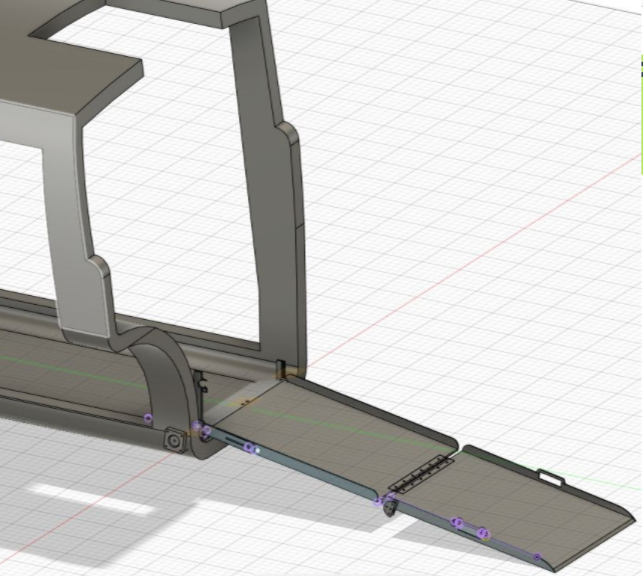

Wheelchair Accessible Tesla Project

2020-2021 - Spring

Team: 3

General Atomics: Robotic Handling

2020-2021 - Spring

Team: 13

Hamud Universal Upright Vehicle Rack

2020-2021 - Spring

Team: 29

Formula SAE Traction Control

2020-2021 - Spring

Team: 12

XLence AM 3D Inertion Printer

2020-2021 - Spring

Team: 27

Team Members

Team Member 1: Adan Ruiz

Team Member 2: Puning Zhu

Team Member 3: Kennan Gonzales

Team Member 4: Bradley Robison

Team Member 5: Martyn Lizarraga

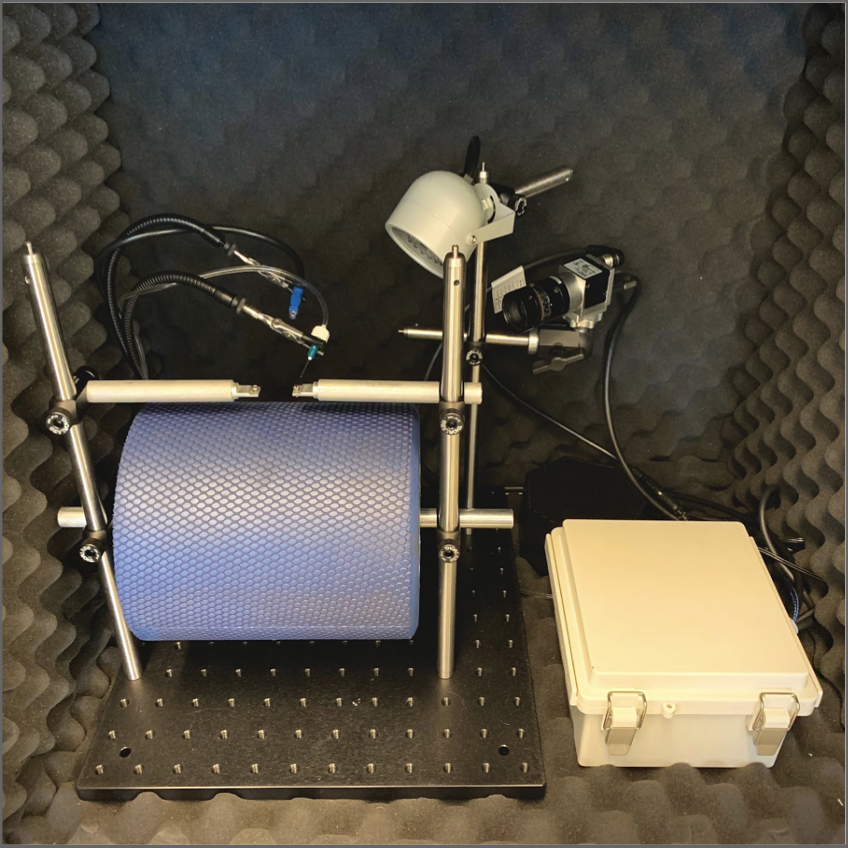

Improving Automated COVID-19 Testing Workflows: Pipette Challenge

2020-2021 - Spring

Team: 32

Cohu Temperature Control

2020-2021 - Spring

Team: 20

Team Members

Nathan Zager

Matthew Soohoo

Harrison Lew

Emmanuel Gharehbekloo

Ronald Law

Development of Advanced Hose Clamp

2020-2021 - Spring

Team: 18

Solar Turbines: Ancillary Quick Disconnect

2020-2021 - Spring

Team: 16

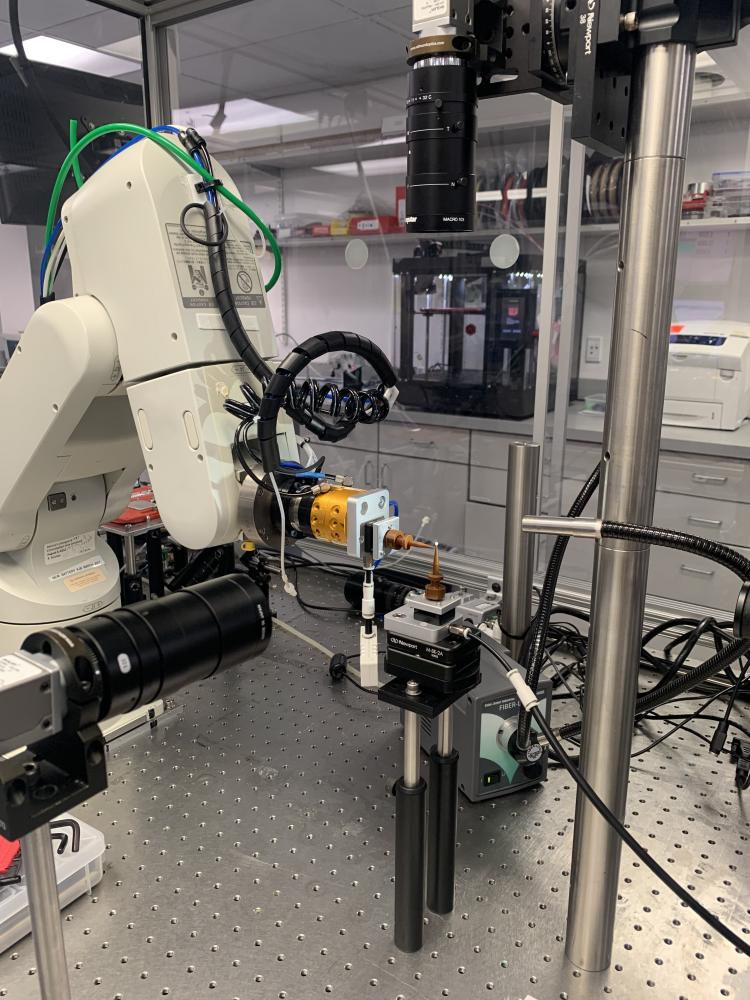

Cerebellar Dependent Learning

2020-2021 - Winter

Team: 19

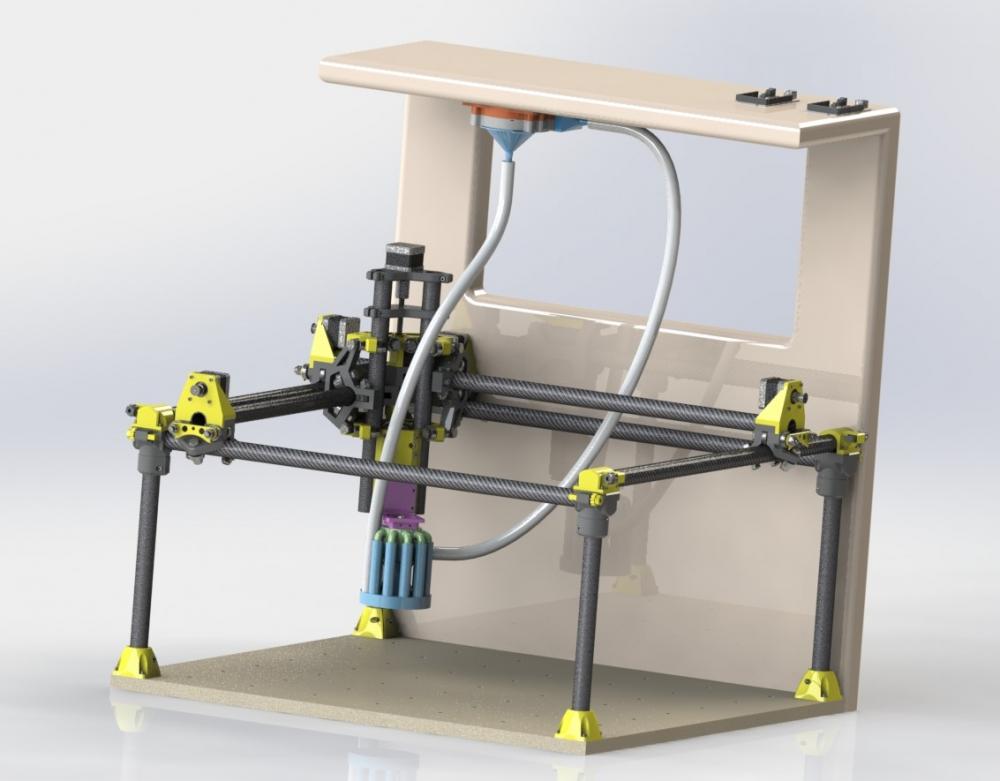

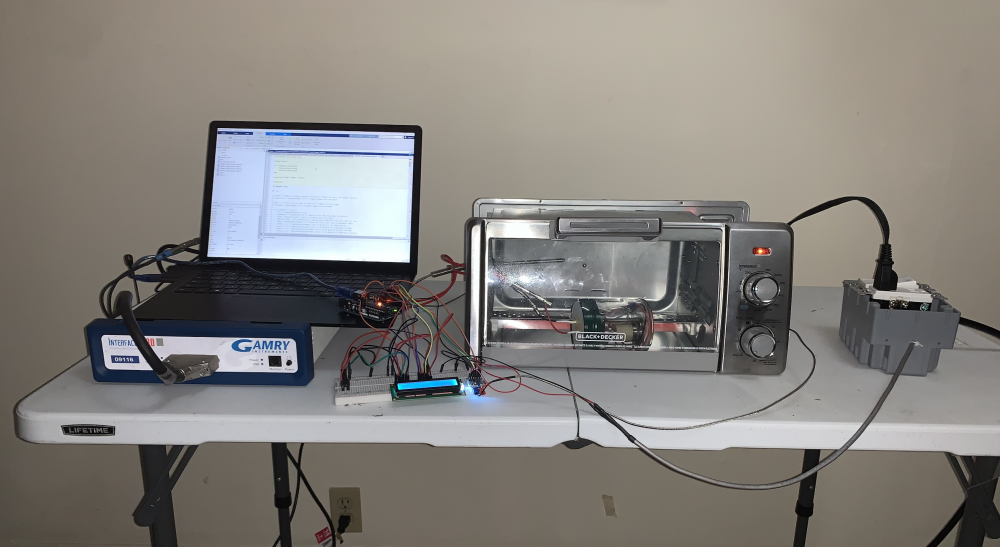

Automated Control of Material Structure with Electrical Impedance Monitoring

2020-2021 - Spring

Team: 4

UCSD Medical - Blood Pressure Cuff

2020-2021 - Spring

Team: 9

Team Members

Austin Chung

Albert Hernandez

Jeffrey Onuma

Jordan Wong

Articulet: An Articulating Endotracheal Tube Stylet

2020-2021 - Spring

Team: 36

Precious Plastic

2020-2021 - Winter

Team: 17

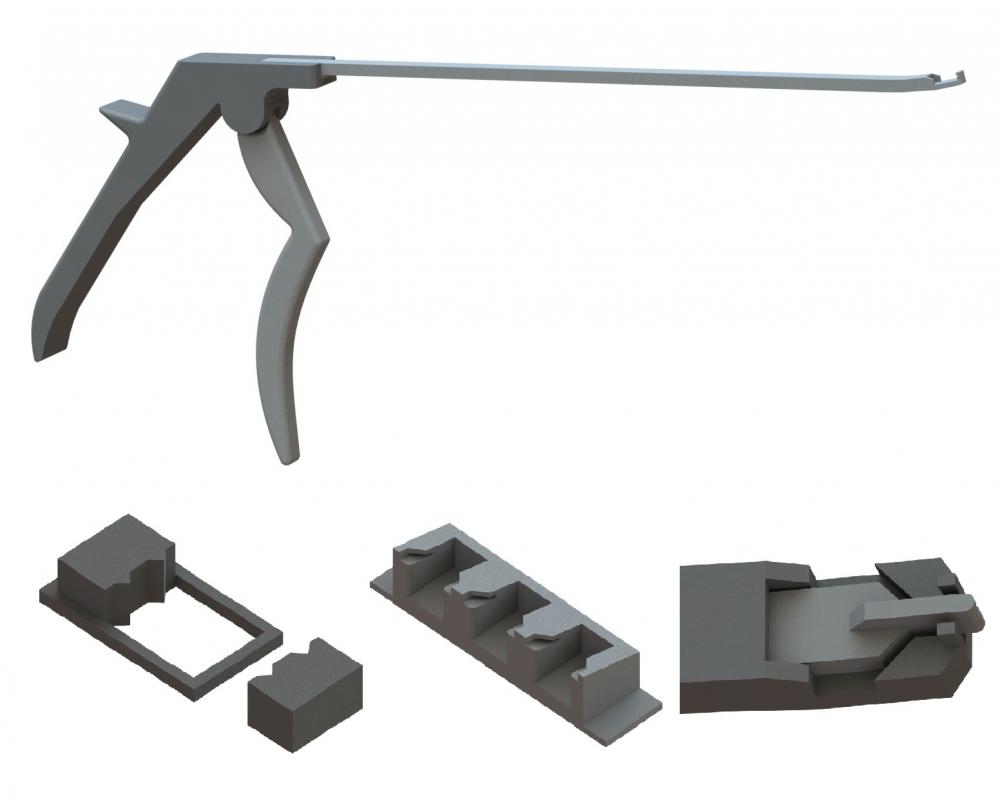

Endoscopic Tissue Stapler

2020-2021 - Spring

Team: 34

Endoscope Torque Applicator

2020-2021 - Spring

Team: 35

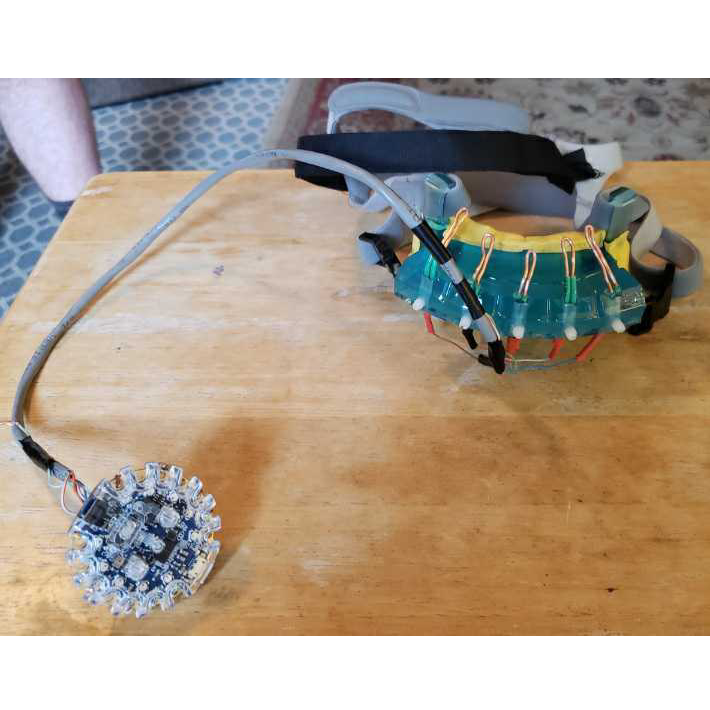

Adjustable Head Mount for Augmented Reality Facial Motion Tracking System

2020-2021 - Winter

Team: 15

Tongue Touch Mouse & Keyboard

2020-2021 - Spring

Team: 8

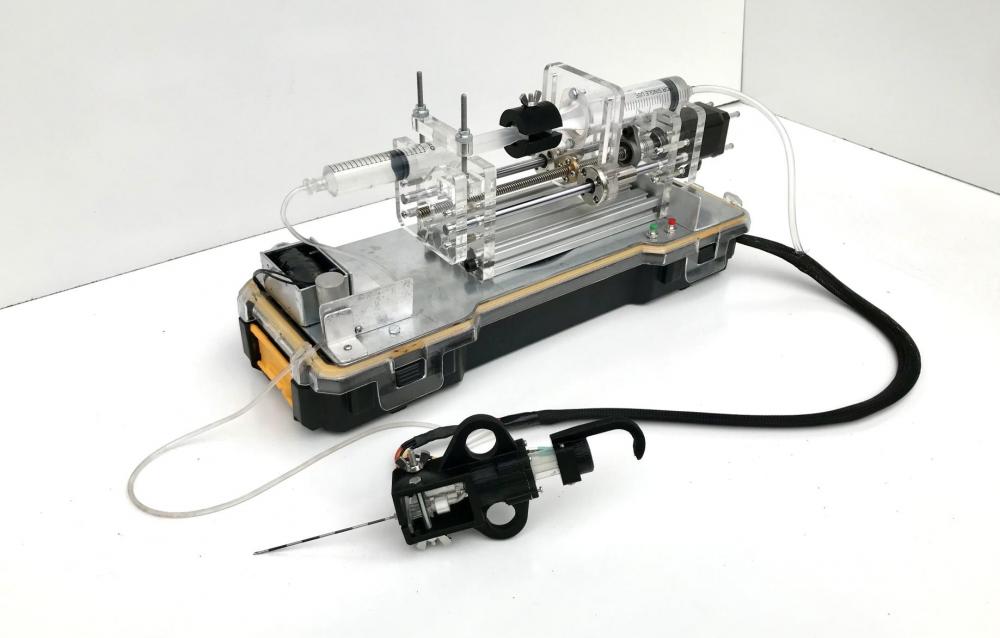

UCSD MED - Autoinjector for Ultrasound Guided Nerve Blocks

2020-2021 - Spring

Team: 31

DIII-D DiMES Port Rod Ablation System

2020-2021 - Spring

Team: 17

Team Members

Michael Hanson

Jason Escalera

Hadith Taheri

Daniel Zubovic

Caitlin Villareal

Bike Helmet Task Light

2020-2021 - Spring

Team: 15

Hair Snag Project

2020-2021 - Spring

Team: 28

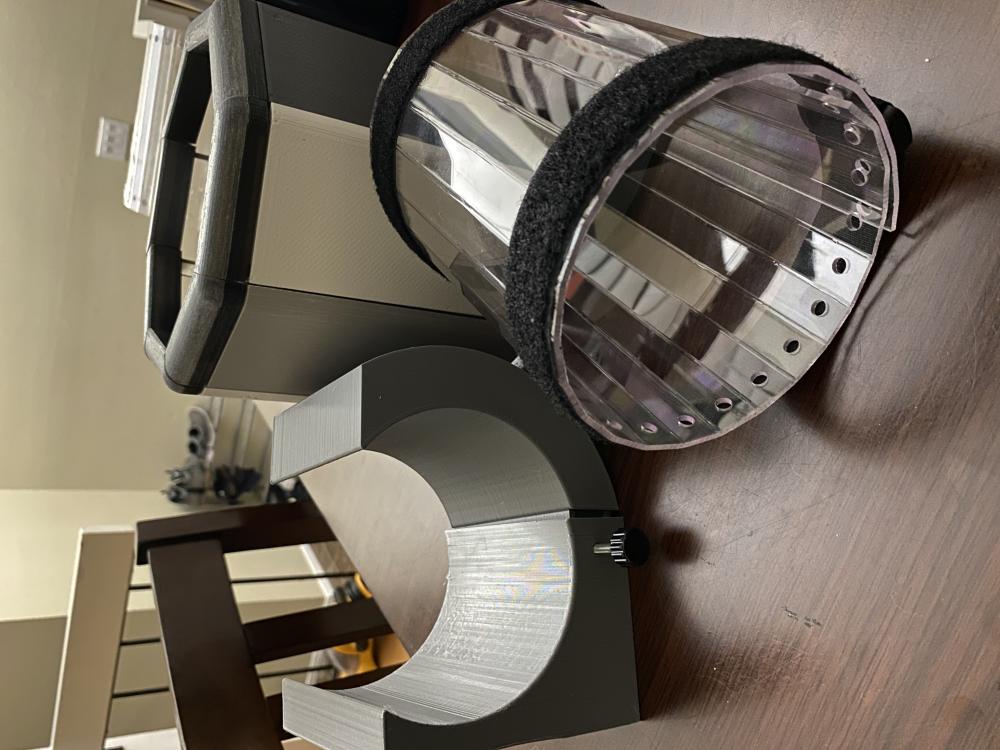

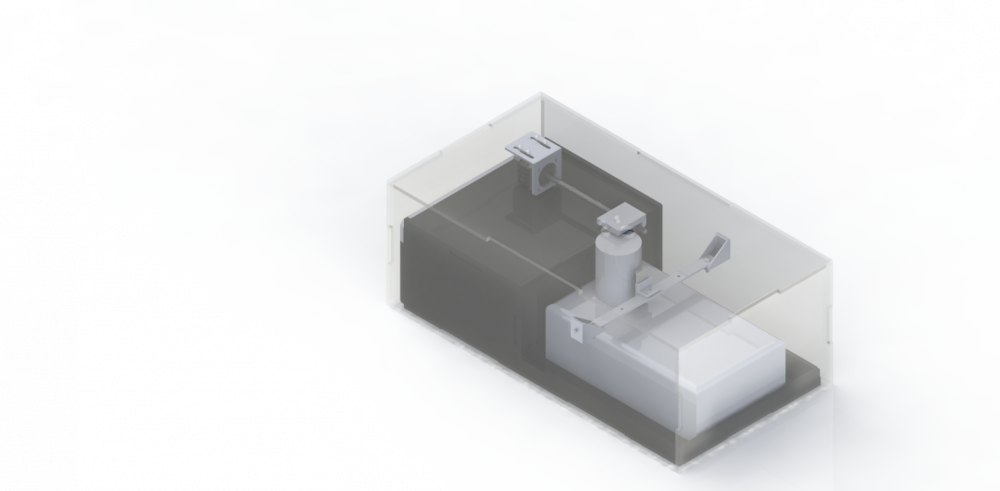

Automated Solubility Measurement

2020-2021 - Spring

Team: 25

Team Members

Owen Cruise

Yaxin (Cindy) Guan

Kristin Hartsfield

Brandon Lansang

Cade Wohltman

Wearable Countermeasure Device

2020-2021 - Spring

Team: 30

Team Members

Nicholas Ashforth

Nathan Burdick

Keva Chin

Nathan George

Mario Miguel

2 Stage Refrigeration

2004-2005 - Spring

Team: 11

Team Members

Jozefik Zoltan

Roy Z. Li

Tom Y. Lee

Jayson Q. Shi

Non-contact Temperature Control

2004-2005 - Spring

Team: 12

Team Members

Jason Poulos

Wendy Chen

Nicholas Matteson

Kyaw Win