Previous ASME Award Winner

Recent Departmental Runner Up Awards

Capstone Design Projects

Animal Care Processing Project (ACCP)

2024-2025 - Spring

Team: 42

Material Transfer Cleaning

2024-2025 - Winter

Team: 2

MRI Stereo

2024-2025 - Spring

Team: 5

Scripps Anemometer Drone

2024-2025 - Spring

Team: 41

UCSD Med Nerve to Smile

2024-2025 - Spring

Team: 13

Endoscopic Multiload Clip Applier

2024-2025 - Winter

Team: 5

Quantum Engineered Nano Device

2024-2025 - Spring

Team: 4

Team Members

Scott Ceklarz

Kalie Garcia

Satchin Narasimhan

Unlocking the Door with AI

2024-2025 - Spring

Team: 40

UCSD Med Low Cost Microsurgery Instruments

2024-2025 - Spring

Team: 14

Flow Enabled Energy Generation Device

2024-2025 - Winter

Team: 4

Team Members

Ashley Campbell

Maime Grace Barnard

Gabrielle Scott

Markus Gokan

Justin Kwak

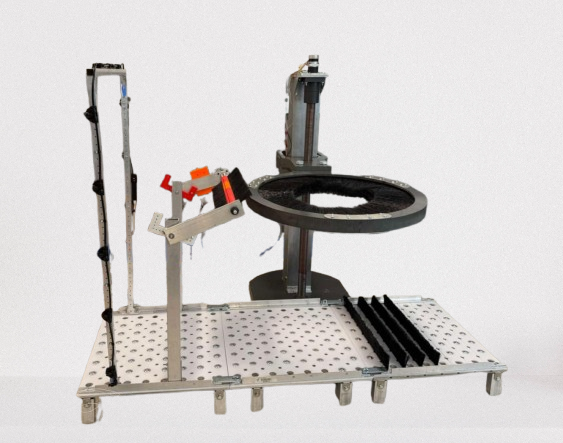

Random Positioning Machine 2.0

2024-2025 - Spring

Team: 31

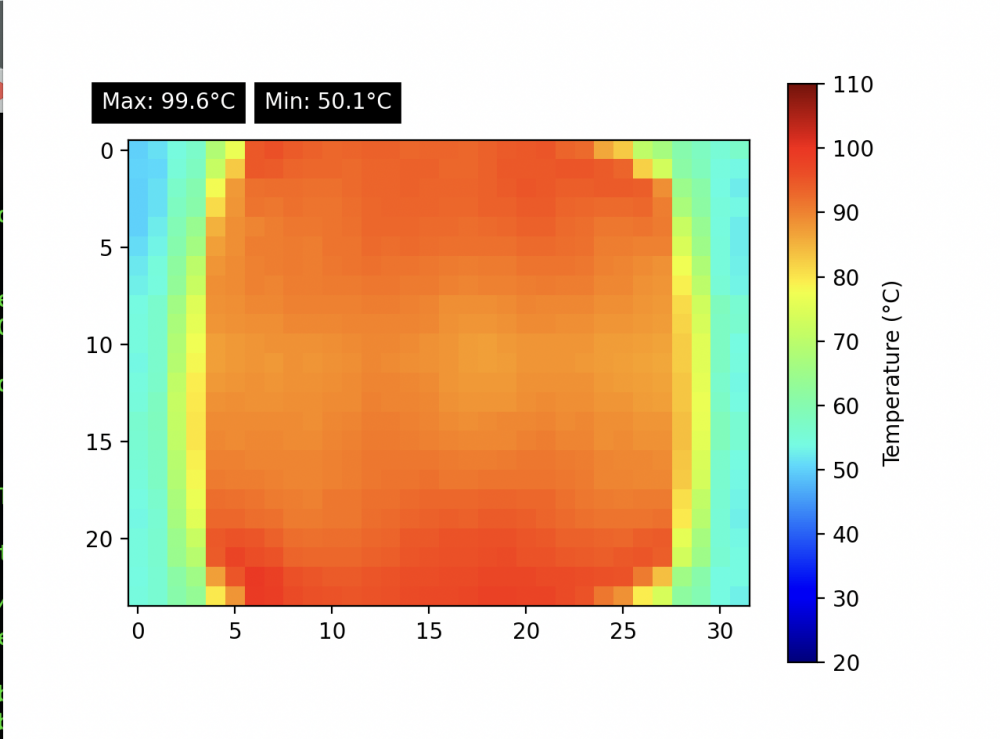

Cohu Temperature Gradient Tester

2024-2025 - Spring

Team: 36

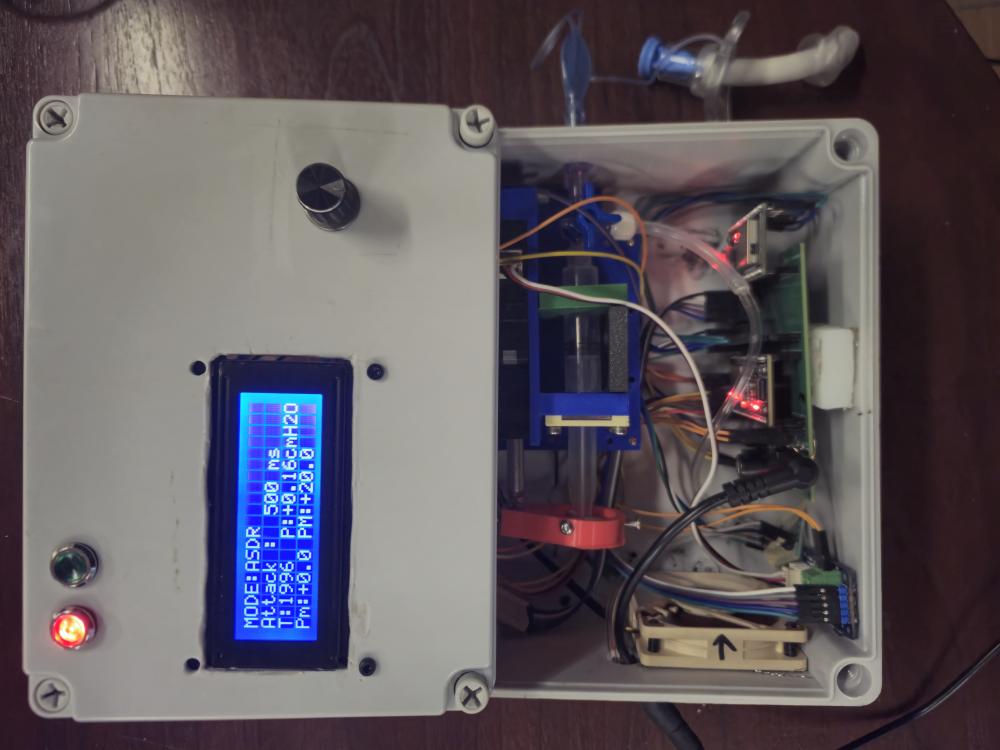

Automated Tracheal Cuff Pump

2024-2025 - Winter

Team: 6

Jacobs Hall Clock Revival

2024-2025 - Spring

Team: 33

Team Members

Jonathan Dela Cruz

Irving Ding

Fatima Fazli

Fernando Gochicoa

Lacey Potter

Improved Punch Biopsy Tool

2024-2025 - Spring

Team: 35

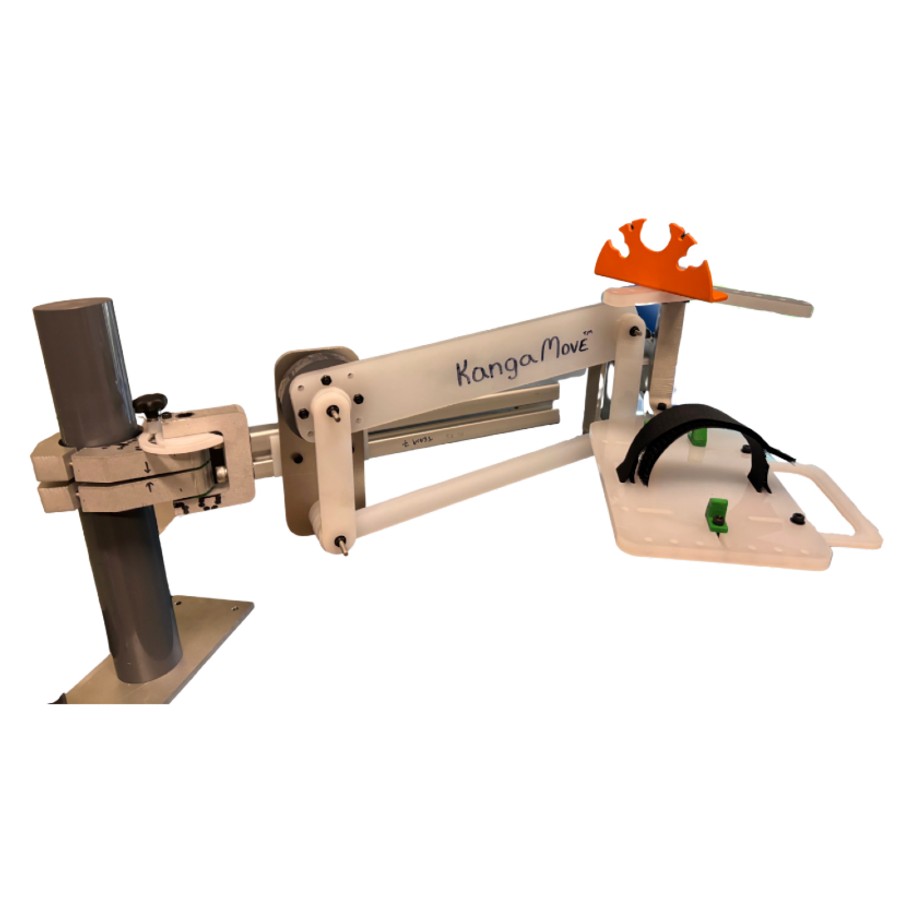

KangaMove Parental Skin-to-skin Contact Support

2024-2025 - Winter

Team: 7

Autogyro UAV

2024-2025 - Spring

Team: 22

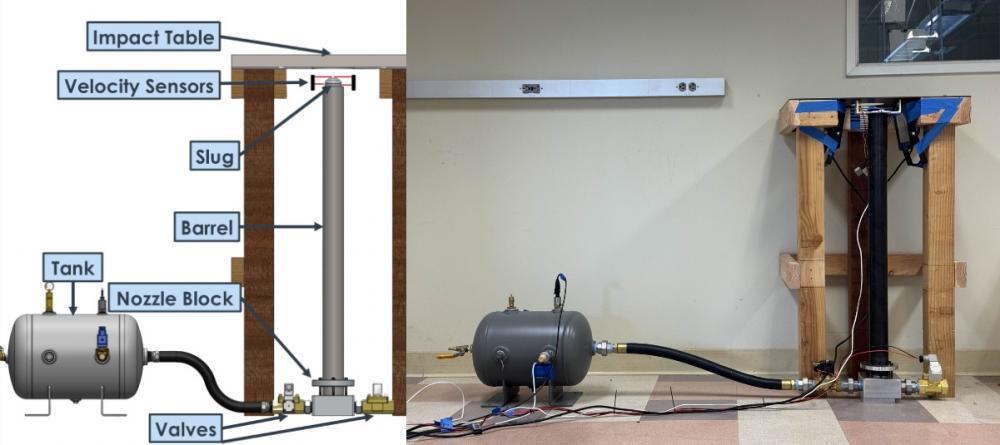

ATA Shock Test Table Firing Mechanism

2024-2025 - Spring

Team: 1

Team Members

Manu Mittal

Nina Abraham

Marco Rincon Villanueva

Anne Marlow

Reggie Estrella

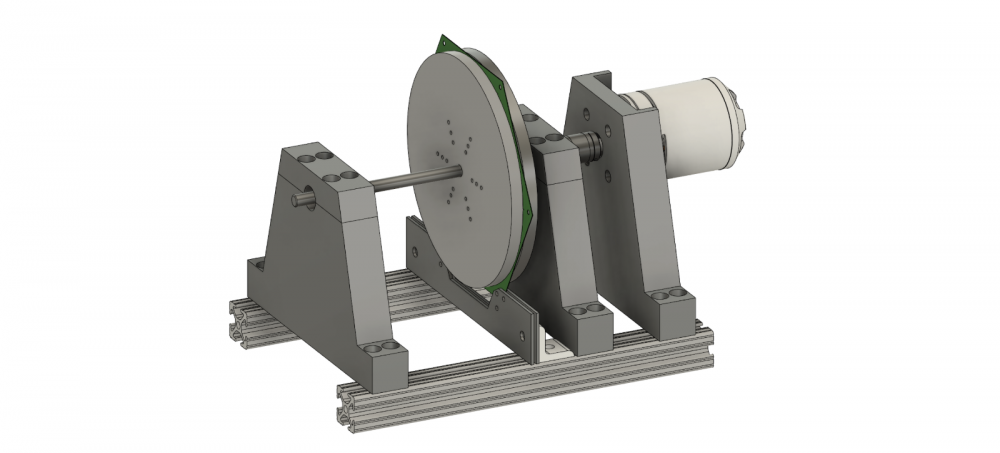

Unmanned Aerial Systems Hybrid Powertrain Testbed

2024-2025 - Winter

Team: 3

Team Members

Daniel Cruz-Espada

Jason Holtkamp

Joud Bukhari

Kenneth Su

Shivharsh Kand

Ziad Gari

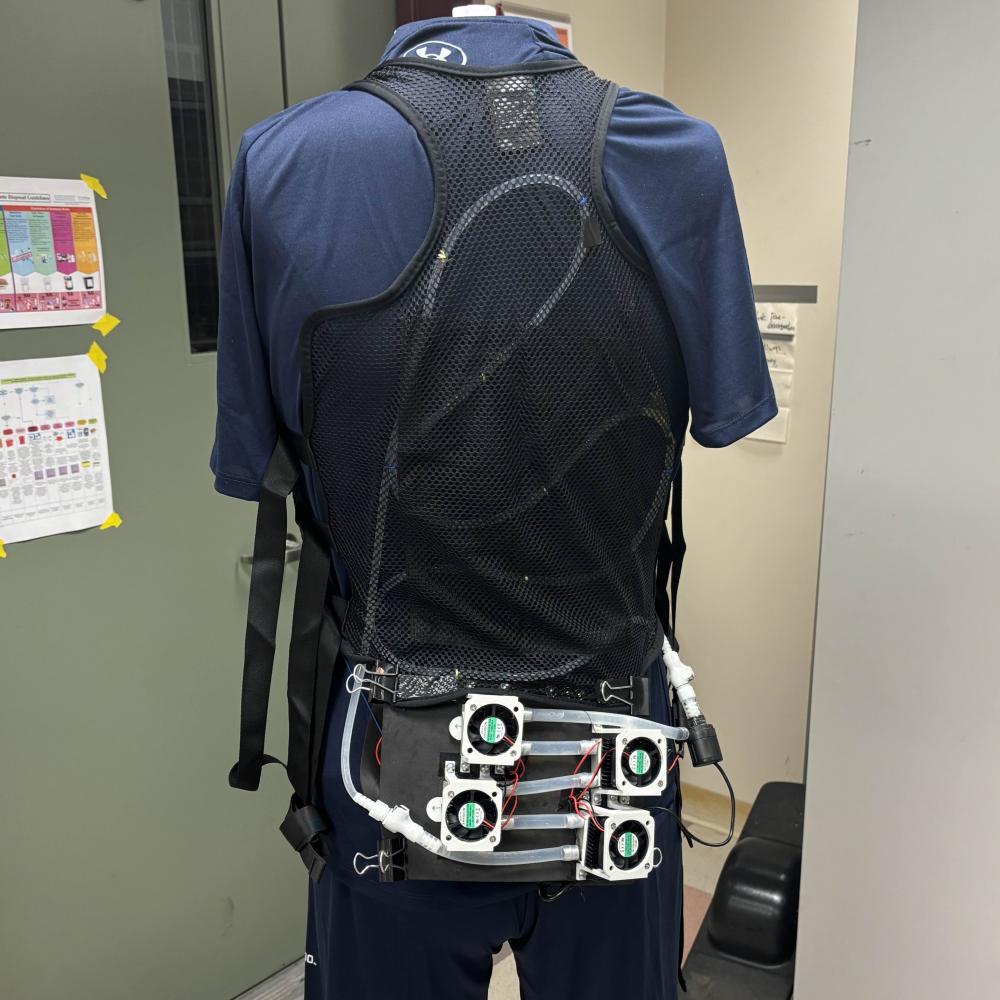

Portable TEC-Based Liquid Cooling Garment

2024-2025 - Spring

Team: 30

Team Members

Aaron Lo

Morgan Laney

Fatima Rivera

Karla Ramirez

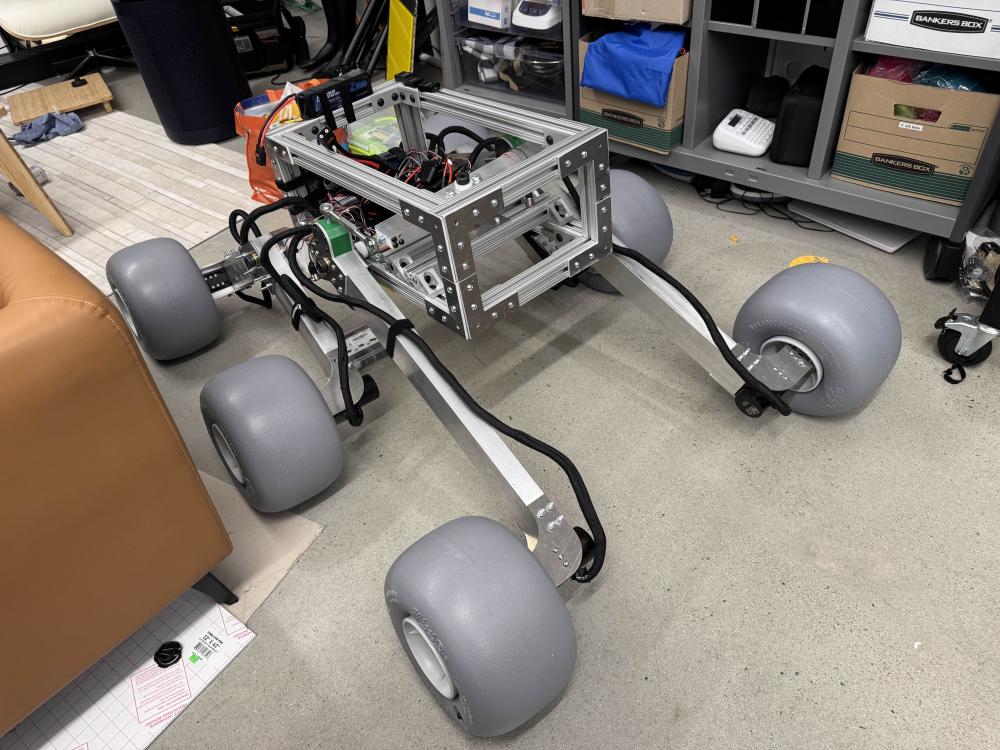

Lifesaver Project Rover Module

2024-2025 - Spring

Team: 39

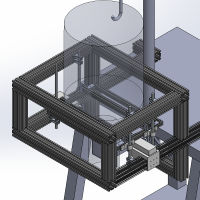

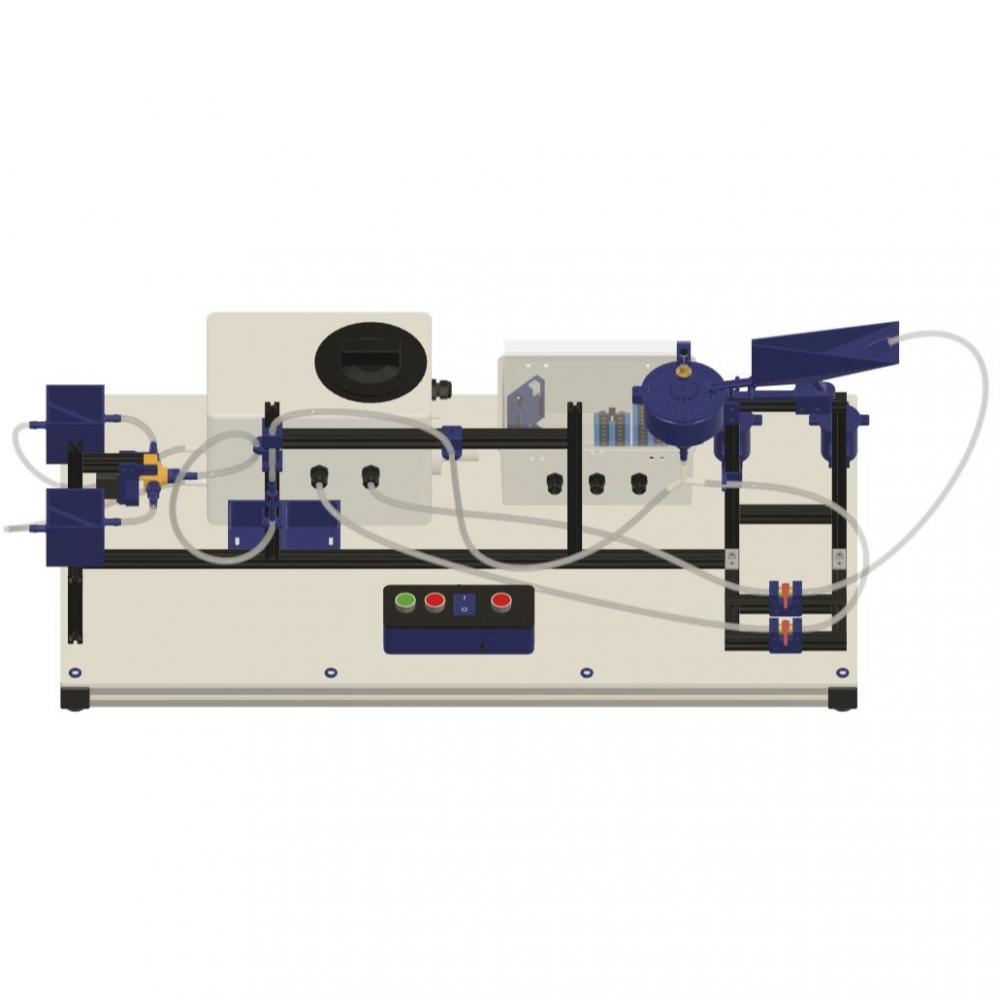

GA - Foam Shell Culling Station

2024-2025 - Winter

Team: 1

Team Members

Tobin Boshaw

Matthew Pope

Collin Huang

Samuel Hasegawa

Kenny Ochoa

Brandon Lopez

Bidirectional Guide for Treatment of Peripheral Artery Disease

2024-2025 - Spring

Team: 21

Kinetic Craft Center Sign

2024-2025 - Spring

Team: 6

Automated Cognitive Touchscreen Training System for Mice

2024-2025 - Winter

Team: 8

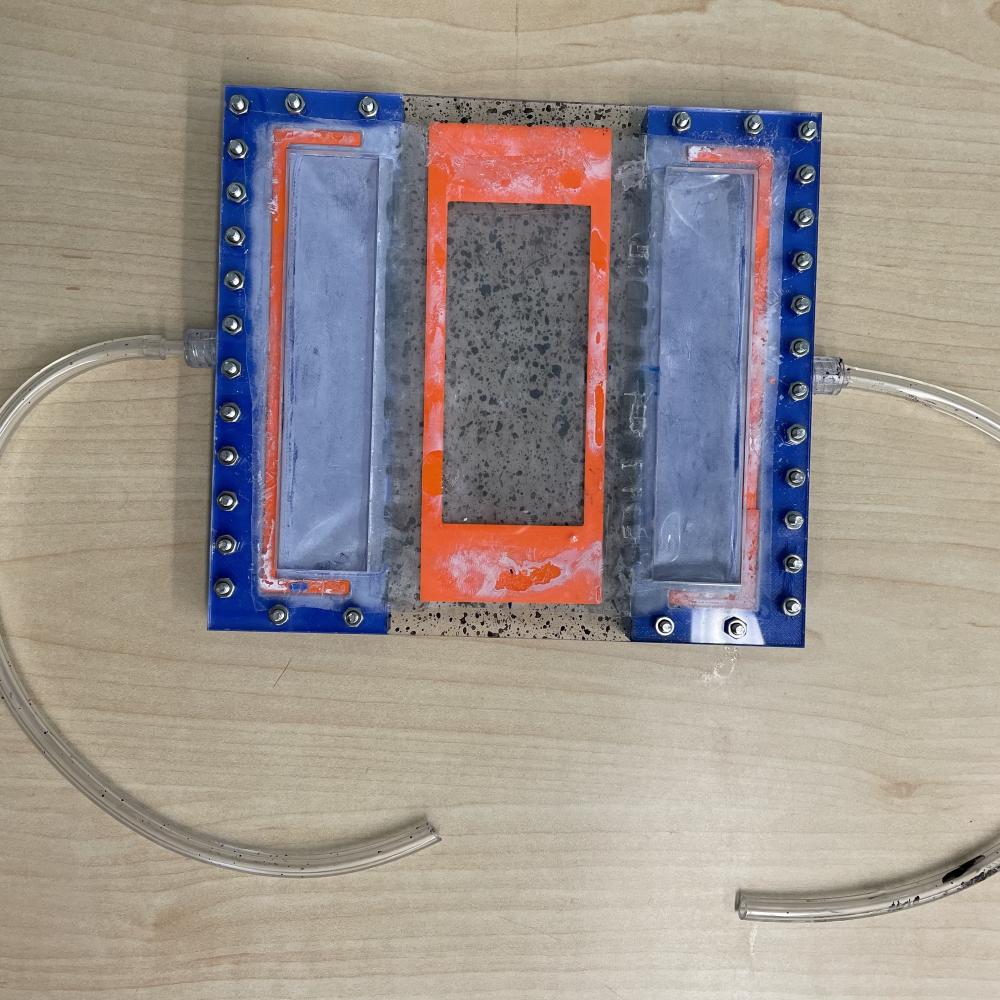

Cell Stretcher 2.0

2024-2025 - Spring

Team: 29

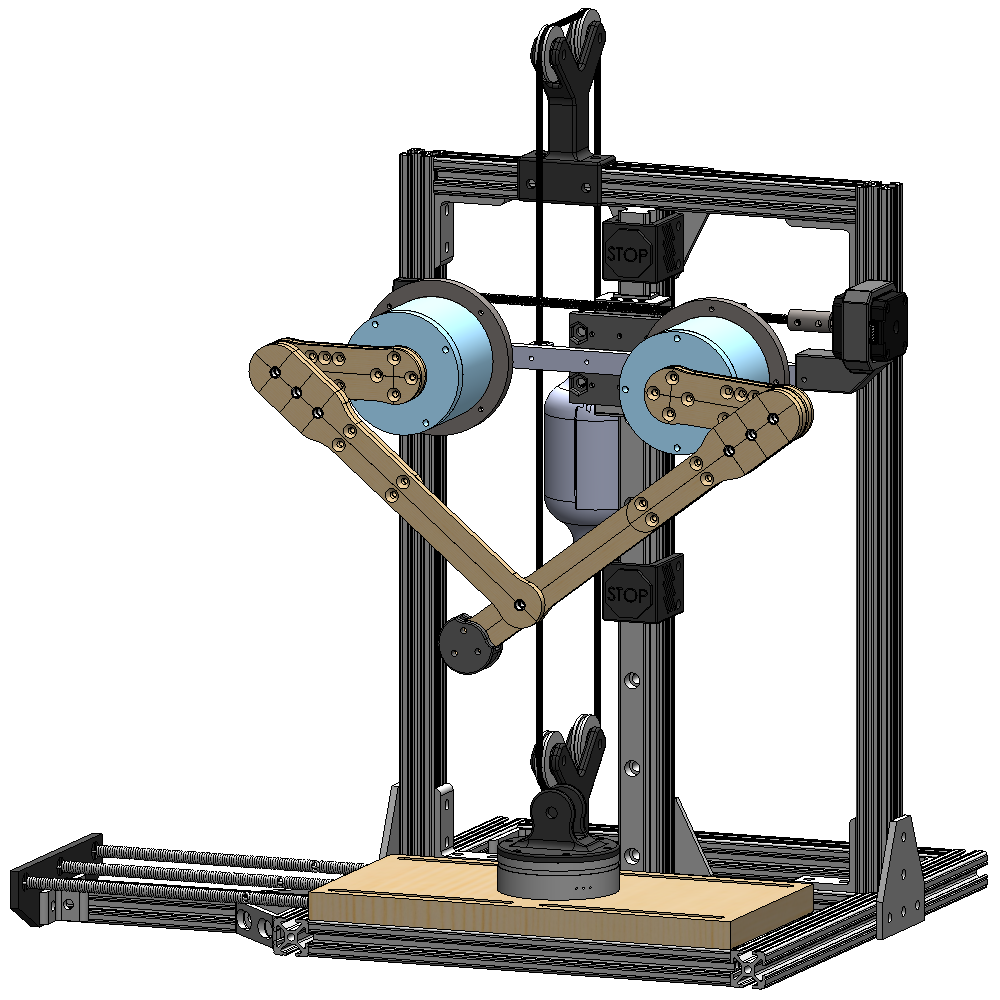

Design and Analysis of a Mode-Transitioning Robotic Leg and Test Bed for a Hexapod Rescue Robot

2024-2025 - Spring

Team: 37

Team Members

William Harris

Lucas Yager

Giovanni Bernal Ramirez

Hwuiyun Park

Elias Smith

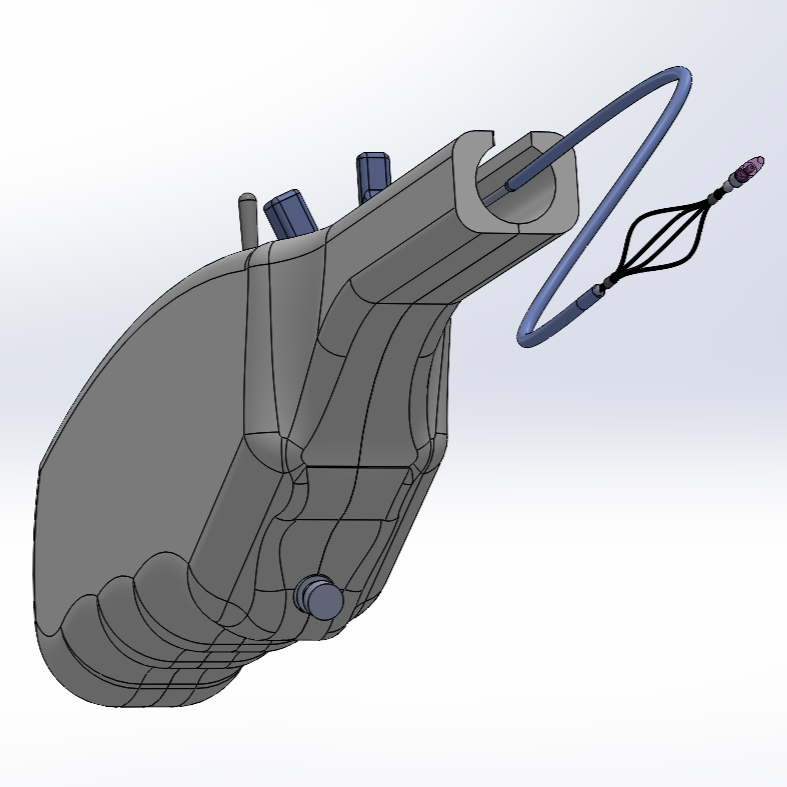

Endovascular Device for Rapid Blood Clot Removal

2024-2025 - Winter

Team: 12

Carbon Blade Carbon Capture

2024-2025 - Spring

Team: 15

Team Members

Ian Cosgrove

Charlie Frank

Juncheng Li

Alexandra Rodriguez

Konrad Stromayer

Materials Break Up

2024-2025 - Spring

Team: 16